In this study, researchers sought to characterize crop responses to semi-transparent organic solar cells (ST-OSCs) in greenhouses. Lettuce and tomato crops were grown under three ST-OSCs filters that created different light spectra. Lettuce yield and early tomato development were not negatively affected by the modified light environment. A genomic analysis revealed that lettuce production exhibited beneficial traits involving nutrient content and nitrogen utilization while select ST-OSCs impact regulation of flowering initiation in tomato. These results suggest that ST-OSCs integrated into greenhouses are not only a promising technology for energy-neutral, sustainable and climate-change protected crop production, but can deliver benefits beyond energy considerations.

Tag Archive for: AgriSolar

In this AgriSolar Clearinghouse webinar, Dr. Greg Barron-Gafford discusses the effects of growing crops under solar panels.

The AgriSolar webinar series continues in March. Sign up for these free webinars, here.

By Tyler Swanson and Quin Karhoff

The Bock Agricultural Law and Policy Program at the University of Illinois, Urbana Champaign is conducting a study supported by the National Renewable Energy Laboratory on the economics of solar grazing. Our research goal is to determine the structure of a solar grazing business, the cost associated with entering the solar grazing market, and a general range of profits a solar grazer can expect to earn in a given year. With this data, we aim to create a free, customizable budget tool that prospective solar grazers can use to gain a better understanding of the cost of entering the market and the revenues they can generate over time.

To accomplish our research goals, we would greatly appreciate you taking a few minutes to complete the survey linked below about your solar grazing operation. Be assured that your identity will be kept confidential.

Further, we understand that your time has value. If you include your email address at the end of the survey, we will send you a $5 Amazon gift card to compensate you for your participation.

Thank you for your assistance and we hope that the findings of our study will be beneficial to your operation. If you have any questions, please reach out to Tyler Swanson at tswans4@illinois.edu

By David McFeeters-Krone, RUTE Foundation Systems, Inc.

Solar development is exploding around the country. The Inflation Reduction Act incentives have exacerbated this trend such that the next 10 years will lead to solar developments on over 2 million acres of land. This extreme growth for renewable energy will put a like amount of pressure on the best solar lands. However, as shown by an Oregon State University study, most of the prime, flat land near load is already in use growing food or for ranching. Agrivoltaics is the answer to the food versus energy dilemma. Ranching holds particular promise, as partial shade has been shown to benefit forage, especially in arid regions.

In an effort to solve this problem, RUTE’s SunTracker agrivoltaic solution was selected as one of the 20 semi-finalists in NREL’s American-Made Solar Prize Round 6. SunTracker plans to use the $50,000 prize to further refine its cattle-grade, high-clearance solution and continue its component certifications at the Oregon Manufacturing Innovation Center, in Scappoose. One of the reasons RUTE was selected for this award is its focus on ranching. Rangeland, particularly for cattle, is generally more available than farmland, but cattle-grade solutions are in short supply or not cost-competitive.

The solution differs from conventional solar with its cable-stayed poles and vertical, single-axis trackers. This design offers height at less cost and less ground disturbance, making it well-suited for ranching. Initial calculations suggest a meaningful reduction of steel use, akin to the reduction of steel in a cable-stayed bridge. Work under this award and other ongoing tests will compare SunTracker’s use of metal, labor, and site prep to create an apples-to-apples comparison with today’s Horizontal Single Access Trackers (HSAT) and reinforced solutions to determine which structure is optimal in different environments.

In addition to these tests, RUTE has plans to install its first set of trackers on a Grant County, Oregon ranch in 2023. The installation—known as the Bear Valley Solar Pasture—will be complete by summer, and RUTE is looking forward to seeing their technology at work on America’s farmland. The hope is that SUNTRACKER’s high-clearance solar will enhance rural economies by no longer forcing a Faustian choice between lucrative solar leases and local jobs.

All photos courtesy of RUTE Foundation Systems, Inc.

This episode features a conversation between Stacie Peterson, NCAT’s Energy Program Director and Manager of the AgriSolar Clearinghouse, and Lexie Hain, the country’s leading solar grazing expert.

It is the third in a series of AgriSolar Clearinghouse podcasts that are being featured on ATTRA’S Voices from the Field podcast.

Lexie is a farmer, solar grazer, and the Director of Agrivoltaics at Lightsource BP. She co-founded the American Solar Grazing Association and is a stakeholder in the AgriSolar Clearinghouse. She also coined the term solar grazing.

Lexie and Stacie discuss the practicalities of solar grazing, how to prepare and manage agrivoltaic sites, opportunities for grazers and solar developers, and how sheep and solar are made for each other.

This material is based upon work supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) under the Solar Energy Technologies Office Award Number DE-EE000937. Legal Disclaimer: The views expressed herein do not necessarily represent the views of the U.S. Department of Energy or the United States Government.

Related NCAT Resources:

- AgriSolar Podcasts Ep. 1: Growing Crops Among the Solar Panels in Colorado

- AgriSolar Podcasts Ep. 2: Keeping Family Farm in Family Hands with AgriSolar in Massachusetts

Other Resources:

- Lighthouse BP – Agrivoltaics & Solar Grazing

- AgriSolar Clearinghouse – Solar Grazing

- American Solar Grazing Association

Have questions or need help? Contact us.

Please complete a brief survey to let us know your thoughts about the content of this podcast.

You can get in touch with NCAT/ATTRA specialists and find access to our trusted, practical sustainable-agriculture publications, webinars, videos, and other resources at ATTRA.NCAT.ORG.

Learn about NCAT’s other innovative sustainable agriculture programs.

By Jessica Guarino and Tyler Swanson

The U.S. agrivoltaics industry continues to grow as the desire to pair solar energy production land uses with pollinator habitats, livestock grazing, and crop production increases. However, while the excitement around agrivoltaics in all its forms blazes a new trail for what solar energy land use can look like, eager landowners and developers face a daunting challenge: state laws and local zoning ordinances that have not considered the possibility that agricultural and solar energy production could feasibly be located on the same tract of land.

Through Agrivoltaics in Illinois: A Regulatory and Policy Guide, researchers at the University of Illinois Urbana-Champaign’s Bock Agricultural Law & Policy Program analyze both the state and local laws that will impact agrivoltaic development in Illinois. The guide pays particular attention to county zoning ordinances, each of which define solar energy, and set the requirements necessary to develop it, in their own unique way. Agrivoltaics in Illinois allows landowners and potential solar developers to easily understand the requirements to build solar in their county and may also point developers towards counties where solar energy development faces a lower burden from the zoning board. Further, developers can read through the specific definitions that a county has for solar energy, which may have an impact on the development of agrivoltaics. For example, in many counties, a solar farm is the principal use for the land on which it is located, which could have negative implications for a landowner wishing to practice agrivoltaics and retain the tax benefits associated with land being classified as an agricultural use. Meanwhile, other counties state in their zoning ordinances that a solar installation under a specified acreage is considered a “solar garden” and thus is classified as either an accessory or special use of the land.

Agrivoltaics in Illinois: A Regulatory and Policy Guide, while focused on analyzing the state laws and local zoning ordinances of Illinois, aims to inform all landowners, farmers, and solar energy developers of the types of laws and ordinances that should be taken under consideration when exploring the deployment of an agrivoltaic system. This guide is also a resource for state and local policymakers seeking to understand what impacts existing policies may have on the development of agrivoltaics. For example, the Renewable Energy Facilities Agricultural Impact Mitigation Act is a state law requiring a deconstruction plan for wind and solar energy facilities when they reach their end of life that also provides assurances to the landowners that the land will be restored for agricultural use, which will impact agrivoltaic installations. Additionally, a local official could review the numerous figures and tables in the guide to understand what solar energy requirements are most common, as definitions and requirements for solar energy facilities vary by location.

As the agrivoltaics industry grows, it will become increasingly important to understand the regulatory framework in which it will exist. Many current zoning ordinances consider solar energy a threat to agriculture and regulate the industry accordingly, which may inhibit the ability of eager farmers and solar developers to deploy the practice. Likewise, state governments have the power to influence the development of agrivoltaics through laws such as the Renewable Energy Facilities Agricultural Impact Mitigation Act. With the legal analysis presented in this policy guide, the authors hope that it will be used by stakeholders to foster informed agrivoltaic regulations and deployment of the practice.

Photos: AgriSolar Clearinghouse

By Anna Richmond-Mueller, NCAT Energy Analyst

From filtering water to creating habitats for other marine species, oysters are a vital component of the Chesapeake Bay’s ecosystem. On land, they are the center of a rich cultural heritage as one of the region’s most valuable fisheries. Generations of families have made a living harvesting the bivalves, whose reefs were once so large that they posed navigational hazards for ships traversing the Bay. However, decades of pollution, disease, and overharvesting have devastated the oyster population. Modern restoration efforts and harvesting regulations offer a glimmer of hope for the bivalve, and Solar Oysters is making a big impact with its revolutionary oyster-production platform powered by solar.

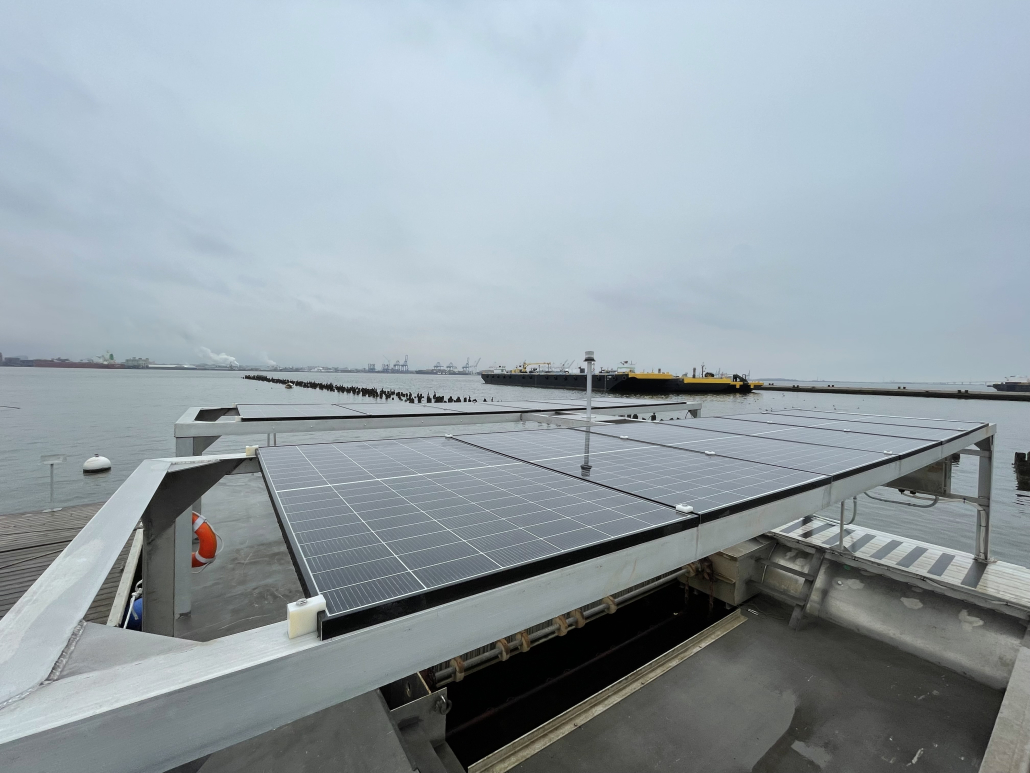

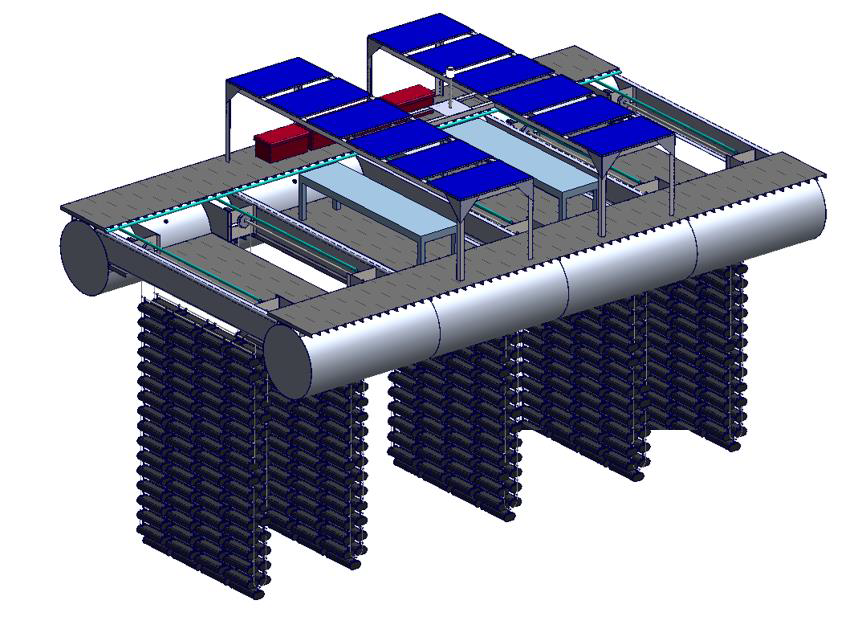

Prior to the establishment of Solar Oysters, the idea to create a floating solar array came to Mark Rice, President of the Baltimore-based engineering firm Maritime Applied Physics Corporation (MAPC), while he was working on a project on the Chesapeake Bay. A local power plant utilized Chesapeake Bay water to cool the plant, and there was a growing interest in mitigating thermal discharge into the Bay. Rice and his team decided the best course of action was to remove incident solar energy from the water to offset the thermal effluent. They knew solar panels would generate valuable electrical energy while also helping to keep water temperatures down and began designing floating solar platforms to tackle the problem. As they were planning the floating arrays, they realized a source of ballast was needed to weigh down the systems and found an opportunity to help improve oyster aquaculture in the Bay simultaneously. Led by Steve Pattison, the environmental strategy firm EcoLogix Group collaborated with MAPC to provide valuable insight about stakeholder engagement, local aquaculture, siting, and environmental permitting. The two companies formalized their relationship in 2019 with the launch of Solar Oysters LLC. By October 2021, Solar Oysters had raised enough money through private funding to construct the first Solar Oyster Production System (SOPS) prototype—a floating high-density oyster-production system automated through solar energy—in Baltimore Harbor.

Measuring 40’ by 25’, the platform has 12 375-watt solar panels attached to the roof capable of generating 36 kWh, alongside four on-board batteries with a 14.4 kWh storage capacity. The solar array powers a system of five vertically rotating ladders on timers, each consisting of 23 rungs capable of holding up to five oyster baskets per rung. This provides a maximum capacity of 575 baskets. As the ladders rotate, the oysters are exposed to different water quality parameters, including temperature, salinity, and dissolved oxygen, resulting in uniformity among all ladder basket positions. At the top of the rotation, the baskets are completely out of the water and exposed to sunlight before resubmerging as the next rung peaks. A manual spray wash system is mounted onboard and pulls water directly from the Bay, allowing those tending the platform to clean the baskets and oysters as needed.

Compared to traditional oyster farming methods, the SOPS platform brings a technological advancement to an industry that has not changed considerably in decades. On farms where the oysters are grown at surface level in floating cages, workers must manually flip each cage over to prevent biofouling. Biofouling refers to the accumulation of organisms such as algae, barnacles, or mussels on the oyster shells and equipment, thus impeding the growth of the oyster population. SOPS greatly reduces the manual labor needed to keep the oysters healthy, thanks to the rotating ladders and spray system. Moreover, the system’s vertical design drastically increases the number of oysters produced per acre. While a traditional float farm may produce between 250,000 and 400,000 oysters per acre, SOPS can produce up to 250,000 oysters on one 0.02 acre-sized barge. This small footprint is an advantage in securing permits or leases compared to a traditional farm that often requires permitting several acres.

Solar Oysters’ first growing season was in partnership with the Chesapeake Bay Foundation as a participant in the Baltimore Harbor oyster gardening program. A grant from the Abell Foundation afforded Solar Oysters the opportunity to onboard spat-on-shell oysters in the fall of 2021. After the 2022 growing season, about 40,000 oysters were transplanted to the Chesapeake Bay Foundation’s sanctuary reef at Fort Carroll, where they significantly helped to advance the Foundation’s oyster-restoration efforts. That same day, Solar Oysters accepted an additional 490,000 spat-on-shell oysters for the upcoming 2023 growing season. Concurrently, seed oysters were being grown to evaluate the effectiveness of the SOPS technology for the oyster consumption market, onboarded at the same time as the first spat-on-shell cohort. After 12 months of growth, the seed oysters measured between 2.5 and 3 inches in length, a size that could take 18 to 24 months to reach using traditional growing methods.

Solar Oysters’ goal is to develop, manufacture, and sell the SOPS technology to organizations focused on oyster restoration or growing oysters for market. In 2023, they plan to continue research on the SOPS platform as they narrow down the best practices for growing oysters on the prototype. Other improvements to the system will include installing a semi-automated spray wash system that replaces the current manual one onboard. The 2023 season will also see Solar Oysters continue to contribute to restoration efforts in the Chesapeake Bay. With such an encouraging first growing season of both spat-on-shell and seed oysters, the technology has the potential to address environmental concerns while also modernizing oyster aquaculture for growers in the Chesapeake Bay and beyond.

All photos courtesy of Solar Oysters LLC.

In this study, researchers examined the impacts of animal agrivoltaics on the thermal comfort and wellbeing experienced by dairy heifers, and the potential benefit of offsetting enteric methane emissions. The shade provided by the solar panels efficiently relieved the heat load on the cattle, cooled off their body surface and skin temperatures, and decreased the costs of thermoregulation. Researchers concluded that 4.1 m2 of solar panels would be necessary to offset the methane emitted by the cows.

In this study, a Consequential Life‐Cycle Assessment (CLCA) was conducted to holistically assess the environmental consequences arising from a shift from single‐use agriculture to agrivoltaic systems (AVS) in Germany. The results of the study show that the environmental consequences of the installation of overhead AVS on agricultural land are positive and reduce the impacts in 15 of the 16 analyzed impact categories.

This work contributes to agrivoltaic design methodology through a digital replica and genomic optimization framework which simulates light rays in a procedurally generated agrivoltaic system at an hourly timestep for a defined crop, location and growing season to model light absorption by the photovoltaic panels and the crop.