This study focuses on the dual use of the water area at a small-scale shrimp farm in western Taiwan for solar photovoltaic electricity generation and aquaculture. Based on the simulation results and SWOT (strengths, weaknesses, opportunities, and threats) analysis, recommendations are made for the design and operation of a solar-powered aeration system for shrimp farms.

Tag Archive for: aquaculture

By Anna Richmond-Mueller, NCAT Energy Analyst

From filtering water to creating habitats for other marine species, oysters are a vital component of the Chesapeake Bay’s ecosystem. On land, they are the center of a rich cultural heritage as one of the region’s most valuable fisheries. Generations of families have made a living harvesting the bivalves, whose reefs were once so large that they posed navigational hazards for ships traversing the Bay. However, decades of pollution, disease, and overharvesting have devastated the oyster population. Modern restoration efforts and harvesting regulations offer a glimmer of hope for the bivalve, and Solar Oysters is making a big impact with its revolutionary oyster-production platform powered by solar.

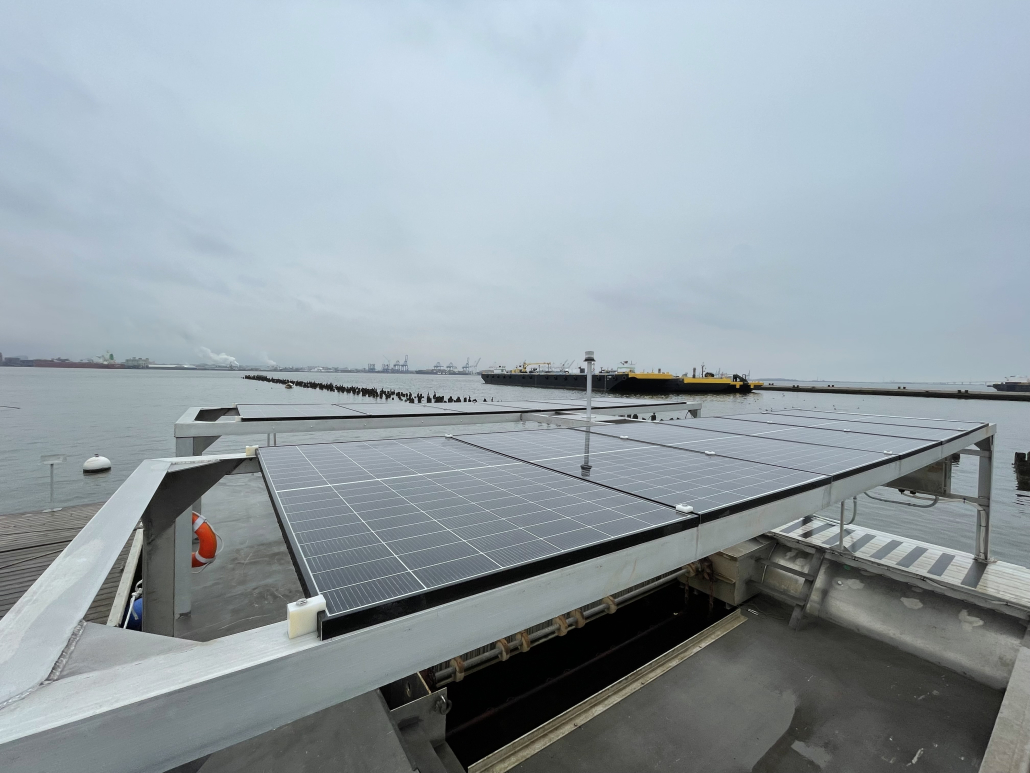

Prior to the establishment of Solar Oysters, the idea to create a floating solar array came to Mark Rice, President of the Baltimore-based engineering firm Maritime Applied Physics Corporation (MAPC), while he was working on a project on the Chesapeake Bay. A local power plant utilized Chesapeake Bay water to cool the plant, and there was a growing interest in mitigating thermal discharge into the Bay. Rice and his team decided the best course of action was to remove incident solar energy from the water to offset the thermal effluent. They knew solar panels would generate valuable electrical energy while also helping to keep water temperatures down and began designing floating solar platforms to tackle the problem. As they were planning the floating arrays, they realized a source of ballast was needed to weigh down the systems and found an opportunity to help improve oyster aquaculture in the Bay simultaneously. Led by Steve Pattison, the environmental strategy firm EcoLogix Group collaborated with MAPC to provide valuable insight about stakeholder engagement, local aquaculture, siting, and environmental permitting. The two companies formalized their relationship in 2019 with the launch of Solar Oysters LLC. By October 2021, Solar Oysters had raised enough money through private funding to construct the first Solar Oyster Production System (SOPS) prototype—a floating high-density oyster-production system automated through solar energy—in Baltimore Harbor.

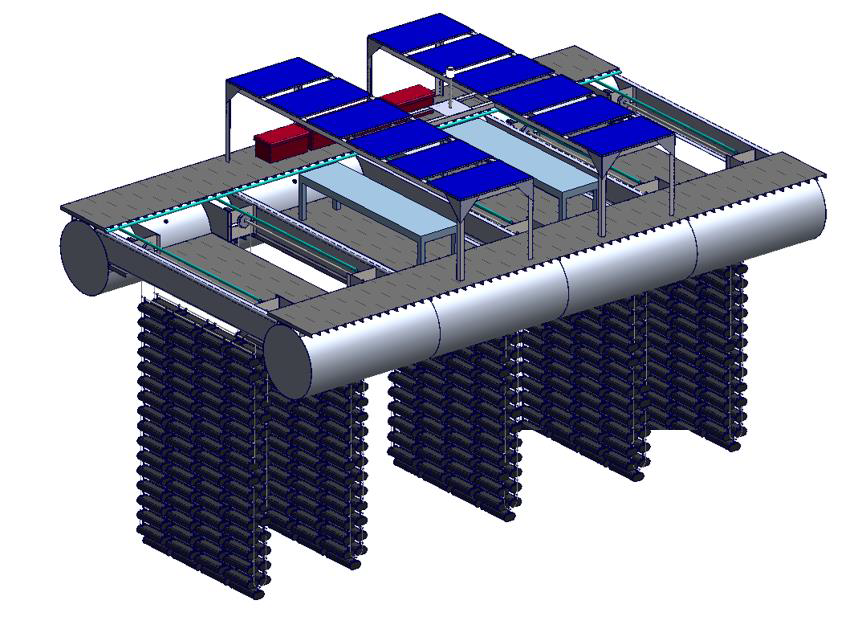

Measuring 40’ by 25’, the platform has 12 375-watt solar panels attached to the roof capable of generating 36 kWh, alongside four on-board batteries with a 14.4 kWh storage capacity. The solar array powers a system of five vertically rotating ladders on timers, each consisting of 23 rungs capable of holding up to five oyster baskets per rung. This provides a maximum capacity of 575 baskets. As the ladders rotate, the oysters are exposed to different water quality parameters, including temperature, salinity, and dissolved oxygen, resulting in uniformity among all ladder basket positions. At the top of the rotation, the baskets are completely out of the water and exposed to sunlight before resubmerging as the next rung peaks. A manual spray wash system is mounted onboard and pulls water directly from the Bay, allowing those tending the platform to clean the baskets and oysters as needed.

Compared to traditional oyster farming methods, the SOPS platform brings a technological advancement to an industry that has not changed considerably in decades. On farms where the oysters are grown at surface level in floating cages, workers must manually flip each cage over to prevent biofouling. Biofouling refers to the accumulation of organisms such as algae, barnacles, or mussels on the oyster shells and equipment, thus impeding the growth of the oyster population. SOPS greatly reduces the manual labor needed to keep the oysters healthy, thanks to the rotating ladders and spray system. Moreover, the system’s vertical design drastically increases the number of oysters produced per acre. While a traditional float farm may produce between 250,000 and 400,000 oysters per acre, SOPS can produce up to 250,000 oysters on one 0.02 acre-sized barge. This small footprint is an advantage in securing permits or leases compared to a traditional farm that often requires permitting several acres.

Solar Oysters’ first growing season was in partnership with the Chesapeake Bay Foundation as a participant in the Baltimore Harbor oyster gardening program. A grant from the Abell Foundation afforded Solar Oysters the opportunity to onboard spat-on-shell oysters in the fall of 2021. After the 2022 growing season, about 40,000 oysters were transplanted to the Chesapeake Bay Foundation’s sanctuary reef at Fort Carroll, where they significantly helped to advance the Foundation’s oyster-restoration efforts. That same day, Solar Oysters accepted an additional 490,000 spat-on-shell oysters for the upcoming 2023 growing season. Concurrently, seed oysters were being grown to evaluate the effectiveness of the SOPS technology for the oyster consumption market, onboarded at the same time as the first spat-on-shell cohort. After 12 months of growth, the seed oysters measured between 2.5 and 3 inches in length, a size that could take 18 to 24 months to reach using traditional growing methods.

Solar Oysters’ goal is to develop, manufacture, and sell the SOPS technology to organizations focused on oyster restoration or growing oysters for market. In 2023, they plan to continue research on the SOPS platform as they narrow down the best practices for growing oysters on the prototype. Other improvements to the system will include installing a semi-automated spray wash system that replaces the current manual one onboard. The 2023 season will also see Solar Oysters continue to contribute to restoration efforts in the Chesapeake Bay. With such an encouraging first growing season of both spat-on-shell and seed oysters, the technology has the potential to address environmental concerns while also modernizing oyster aquaculture for growers in the Chesapeake Bay and beyond.

All photos courtesy of Solar Oysters LLC.