The aim of this research is to establish how relevant agrivoltaics can be in terms of energy production at regional scale. For this purpose, a methodology is developed to: (i) identify greenhouses using cartographic information systems, (ii) estimate how much of these areas could be covered by solar photovoltaic panels without decreasing the crops production, thus, estimating the optimal photovoltaic cover ratio for different type of crops under different solar conditions by developing a novel set of equations and (iii) evaluate the corresponding photovoltaic power and production.

Tag Archive for: Greenhouse

In this study, researchers sought to characterize crop responses to semi-transparent organic solar cells (ST-OSCs) in greenhouses. Lettuce and tomato crops were grown under three ST-OSCs filters that created different light spectra. Lettuce yield and early tomato development were not negatively affected by the modified light environment. A genomic analysis revealed that lettuce production exhibited beneficial traits involving nutrient content and nitrogen utilization while select ST-OSCs impact regulation of flowering initiation in tomato. These results suggest that ST-OSCs integrated into greenhouses are not only a promising technology for energy-neutral, sustainable and climate-change protected crop production, but can deliver benefits beyond energy considerations.

By Anna Richmond-Mueller, NCAT Energy Analyst

When it comes to conversations surrounding energy and water use in the modern world, the agricultural industry’s consumption of both is often at the forefront. As the world’s population continues to grow, humanity is tasked with the challenge of finding ways to meet both food and energy demands across the globe. “I really believe that greenhouse growing is the epitome of sustainable agriculture,” says Soliculture cofounder and CEO Dr. Glenn Alers. Whether it is the ability to greatly increase crop yields when compared to traditional open field growing, or the potential for increased water-use efficiency in combination with hydroponics, greenhouses could play a key role in addressing these concerns. Solar greenhouses also could also play a role in mitigating future energy crises.

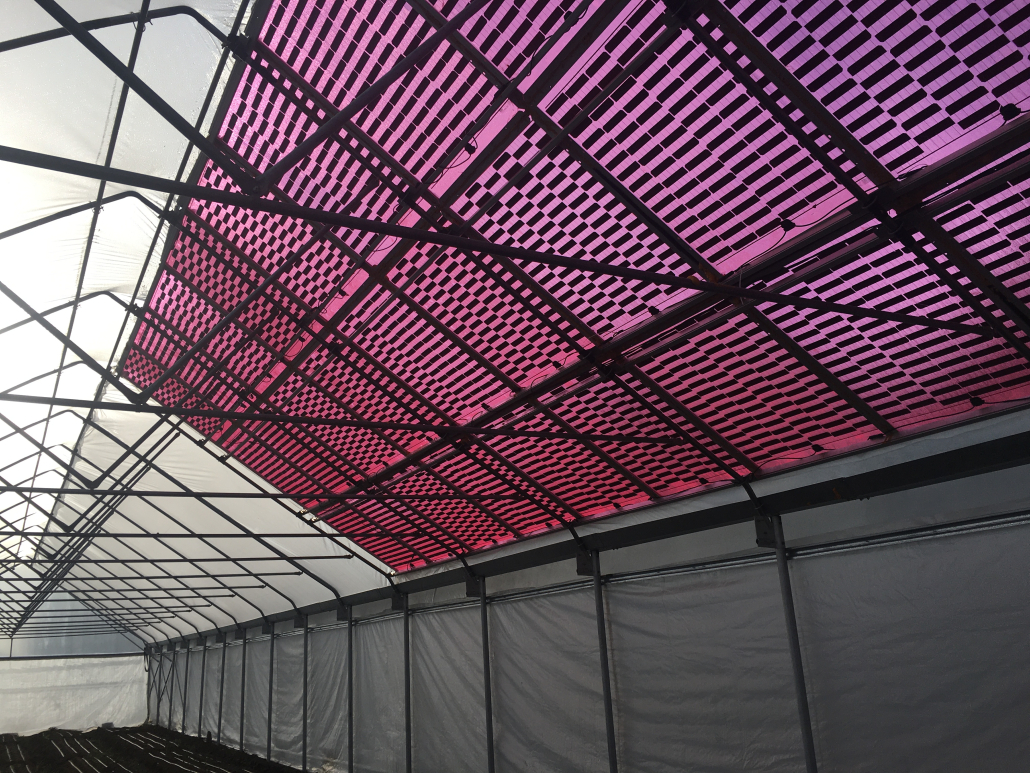

Soliculture began in 2012 as a startup in the Physics Department at the University of California Santa Cruz. Dr. Alers and his cofounder were conducting research on luminescent solar concentrator panels when he realized the technology’s agricultural potential. Luminescent solar panels utilize a luminescent dye that selectively absorbs a portion of the solar spectrum and readmits light at a different wavelength. The dye used in Soliculture panels absorbs the green portion of sunlight with low photosynthesis efficiency and converts it to red light with much higher photosynthesis efficiency. The panels enhance the light quality inside a greenhouse by optimizing the light spectrum for improved plant growth. Moreover, the panels contain bifacial cells that collect the light reflected from the crops planted below them. The red luminescent dye also enhances the power output of embedded cells by 15 to 32%, compared to a conventional panel.

In 2019, Soliculture began a research project on Whiskey Hill Farms in Watsonville, California, aimed at developing these solar panels for use on hybrid high-tunnel greenhouses. As an active organic farm already growing produce in both field and greenhouse settings, Whiskey Hill Farms served as an ideal host for the project. The Soliculture research greenhouse was constructed from the ground up with help from a local high tunnel installer, measuring 120’ long and 25’ wide upon completion. Additional bracing was added to the roof structure, forming a “queen style” truss to support the weight of the panels. One half of the high tunnel was covered by a semi-clear plastic film that served as the control for the upcoming crop growth study, and the other was covered by Soliculture solar panels. These panels were specially designed for high tunnel greenhouses and had a cell coverage of 42%.

The project hit a temporary snag when waterproofing the panel racking system proved to be more of a challenge than expected. At first, horizontal mounting bars were attached to the tubing of the greenhouse’s roof frame and foam weather stripping was installed between the panels to create a watertight seal. Water was still able to leak through at the corners and where the mounting bolts connected the panels to the roof. Knowing the potential for these leaks to cause erosion and negatively impact crop growth, the Soliculture team returned to their laboratory and created a modified racking system specifically for high tunnel application. This new system used mounting brackets that attached to the bottom of the frame and utilized a rubber “T” gasket inserted between the panels to create a seal. Finally, the plastic film portion of the roof was attached to the panels using an aluminum channel screwed into the panel frame and “wiggle wire” to hold the plastic film in position. With a waterproof roof in place, the crop trail was ready to commence.

The following crops were selected for planting following the completion of the high tunnel in mid-November: strawberries, red romaine lettuce, red butter head lettuce, cilantro, mustard greens, and turmeric. To ensure the trial’s results would translate to commercial production, the research team used common commercial growing methods throughout the duration of the trial. These methods included drip irrigation with untreated well water, sand filtration, and liquid organic fertigation. By the end of the trial, the majority of the crops grown under Soliculture panels matured close to two weeks ahead of those grown under the clear film portion of the high tunnel. The fresh weight for the under-panel crops was superior as well, with red butter head lettuce seeing the greatest benefit at 145% higher weight. Mustard greens weighed in at 95% higher, cilantro at 35%, romaine lettuce at 32%, and turmeric at 25%. The strawberry fruit showed no statistically significant difference in fresh weight, but the single 5’ by 120’ planted bed yielded more than 350 pounds of fruit by the end of July.

On top of the very successful crop trial, the power generated by the greenhouse panels was used by Whiskey Hill Farms to power their day-to-day operations. A total of 58 Soliculture panels provided the farm with a 6kW system, which was connected to an inverter. The AC power was then fed back into the farm’s power system, a testament to how greenhouse solar can benefit the farm beyond improving plant growth.

The field of agrivoltaics is constantly evolving, with numerous researchers and farmers searching for the ideal nexus between the agricultural industry and energy production. Soliculture’s contributions to agrivoltaics is important for farmers who have reservations about growing food underneath and around solar panels. “We haven’t seen any negative effect on plant growth,” Dr. Alers says, referring to the Whiskey Hill Farms project and several other successful Soliculture installations across the United States and Canada. Greenhouse production has always had the potential to help alleviate the water crisis and increase the amount of food grown per acre, but Soliculture’s technology is giving it a bright future in energy production, as well.

All photos courtesy of Soliculture

In this study, a donor:acceptor polymer blend is optimized for its use in laminated devices while matching the optical needs of crops. The study reveals degradation modes undetectable under laboratory conditions such as module delamination, which accounts for 10–20% loss in active area. Among the active layers tested, polymer:fullerene blends are the most stable and position as robust light harvesters in future building-integrated organic photovoltaic systems.

This article examines current literature regarding the application of shading systems alongside crop production, with a focus on photovoltaic panels and greenhouse studies. After reviewing 113 articles, the authors conclude that most studies do justify the co-location of photovoltaic panels and crops. However, more crop-specific research is necessary to determine the optimum percentage of panels that will not reduce agriculture production.

This project developed a new racking/mounting system combined with a new specialized solar panel for low-cost implementation in a hybrid high tunnel greenhouse. The project successfully demonstrated that high value crops can successfully be combined with solar electricity production, even resulting in improvements to yields for certain crops.

Agrivoltaic (APV) systems have emerged as a promising solution to reduce the land-use competition between PV technology and agriculture. Despite its potential, APV is in a learning stage and it is still necessary to devote big efforts to investigate its actual potential and outdoor performance. This work is focused on the analysis of APV systems in agriculture greenhouses at global scale in terms of energy yield. In this study, a novel dual APV model is introduced, projected in four representative locations with a high crop cultivation greenhouse implantation, i.e. El Ejido (Spain), Pachino (Italy), Antalya (Turkey) and Vicente Guerrero (Mexico), and for 15 representative plant cultivars from 5 different important socioeconomic families of crops, i.e. Cucurbitaceae, Fabaceae, Solanacae, Poaceae, Rosaceae. At this stage, semi-transparent c-Si PV technology has been considered due its high efficiency and reliability. The results show that APV systems could have a transparency factor around 68% without significantly affecting the total crop photosynthetic rate. Taking this into account, APV systems would produce an average annual energy around 135 kWh/m2, and values around 200 kWh/m2 under a favorable scenario. This could represent a contribution to the total market share between 2.3% (Mexico) and 6% (Turkey), and up to 100% of the consumption demand of greenhouses equipped with heating and cooling (GSHP), and lighting.

The use of renewable energy in modern greenhouse management is important to achieve efficient and sustainable food supplies for a world with increasing population. This study assessed the performance of a blind-type shading regulator that can automatically rotate semi-transparent photovoltaic (PV) blades installed on the greenhouse roof in response to sunlight variation. The PV blind oriented parallel to the roof partially blocked intense sunlight penetration into the greenhouse, but it transmitted sunlight during cloudy time by turning the blind bearing to be perpendicular to the roof. A stable irradiation environment is therefore producible in the greenhouse under variable sky conditions. Annual operations demonstrated that the blinds’ own generated electrical energy can sustain PV blind operation and produce surplus electrical energy. The PV blind electricity generation and sunlight availability for crops below the PV blind roof were calculated based on a mathematical model developed using theoretical sunlight parameters and the experimentally obtained PV blind system parameters. Assuming cloudless skies and threshold irradiance for blind rotation set at 500 W m−2, 13.0 and 12.3kWh m−2 yr−1 surplus electrical energy can be generated, respectively, by north–south and east–west oriented model greenhouses. Cloudy skies reduce surplus electrical energy production by 50%, but PV blinds can supply greenhouse electrical energy demands partially or completely, depending on the degree of greenhouse electrification. Below the PV blinds, 8–10 MJ m−2 day−1 of insolation is expected to irradiate crops under actual sky conditions. This insolation is sufficient to cultivate major horticultural crops. Regulating the threshold irradiance level for PV blind turning can control the sunlight apportionment ratio for cultivation and electricity generation, thereby enabling sustainable energy–food dual production in a greenhouse.

This North Dakota State University Extension publication provides an introductory checklist of energy efficiency opportunities for greenhouses. The checklist includes air leaks, double covering, energy conserving curtain, foundation and sidewall insulation as well as space utilization.