By Stacie Peterson and Chris Lent, National Center for Appropriate Technology

Agrivoltaics is a practice defined as the co-location of crops and grazing under and adjacent to solar photovoltaic panels. The concept of agrisolar co-location goes beyond photovoltaic solar and includes other solar energy production that is not photovoltaic, such as solar thermal. Solar thermal is a term used to describe a technology, such as a crop dryer or solar water heater, that converts the energy from the sun into thermal energy. This thermal energy can be used to heat, dry, and distribute air, water, or heat transfer fluids. Solar thermal principles can be employed in crop drying, processing, and storage, and in water-intensive operations, like dairies.

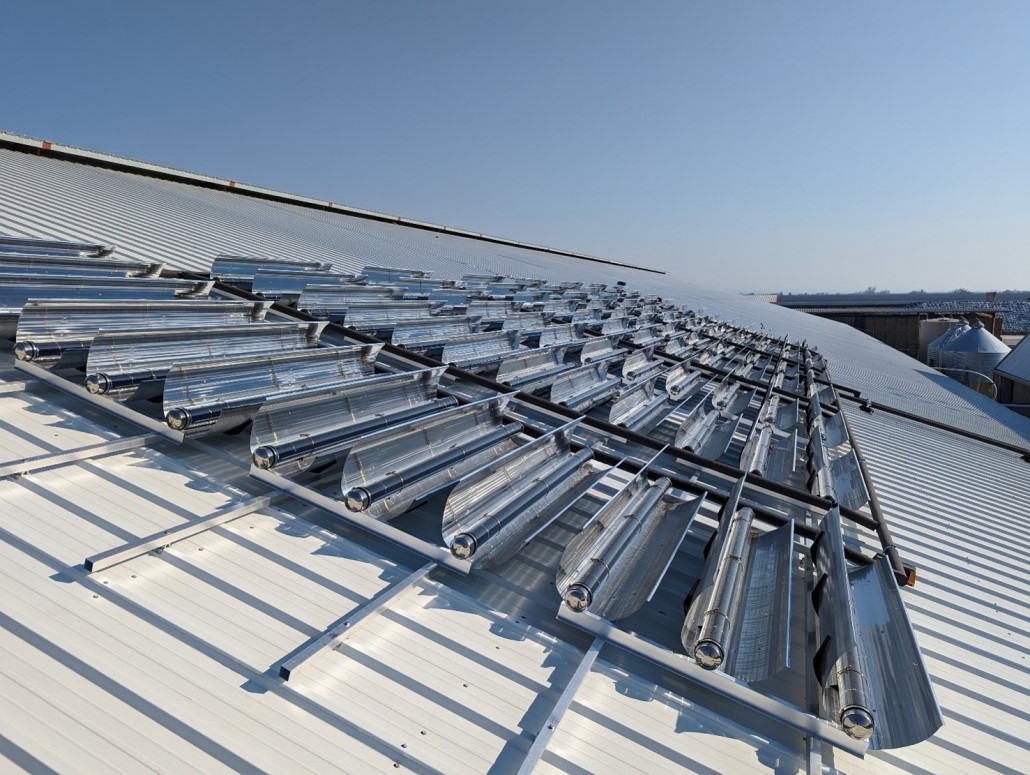

In addition to solar photovoltaic energy production systems, solar thermal energy production is a great way to collect and utilize solar energy. In concentrated solar thermal (CST) production, energy from the sun is concentrated by mirrors, lenses, and parabolic dishes or troughs that reflect the heat energy to a collection point called a receiver. The accumulated energy is then used to power an electric generator. CST systems are often associated with utility-scale electric production; however, CST also has potential applications in commercial water heating, water desalination, and manufacturing. In agriculture, smaller-scale solar thermal systems can be used for crop and grain drying, food processing and drying, greenhouses, and to heat process water for dairies, such as the Winton Cone Optics system shown in in the photo below and described later in this section.

Winston Cone Optics Solar Thermal System. Photo: Winston Cone Optics

Solar Thermal Crop Drying Overview

The sun has been used to dry crops for preservation for millennia. This natural drying process exposes agricultural products to the sun and wind and continues to be used in certain regions to preserve crops because of its low cost and simplicity. It is limited by natural conditions that affect drying, including hours of sunshine and precipitation, which can lead to inconsistent and low-quality results. Sun drying can also be a lengthy process, leaving the crop susceptible to insects, animals, and birds.

Solar thermal drying is a method of dehydrating food crops and grains using solar energy. It’s an environmentally friendly and energy-efficient technique that harnesses heat from the sun to remove moisture from agricultural products and preserve them for periods of storage. Grains, fruits, vegetables, herbs, meat, and fish are some of the agricultural products that are dried to preserve their quality and for use in a variety of value-added products.

Crop dryers can be distinguished by the source of energy used to operate them. Three types are fossil fuel dryers, electric dryers, and solar energy dryers. It takes 2.4 megajoules of energy to evaporate 1 liter of water and most dryers operate at less than 50% efficiency, therefore requiring large energy inputs (Dhumne et al., 2015). Because of the cost to operate fossil fuel-powered and electric crop dryers, solar crop dryers have gained attention as a cost-saving alternative. Small-scale solar dryers have been used around the world, especially in areas where fuel and electricity are scarce and there are favorable sun and weather conditions.

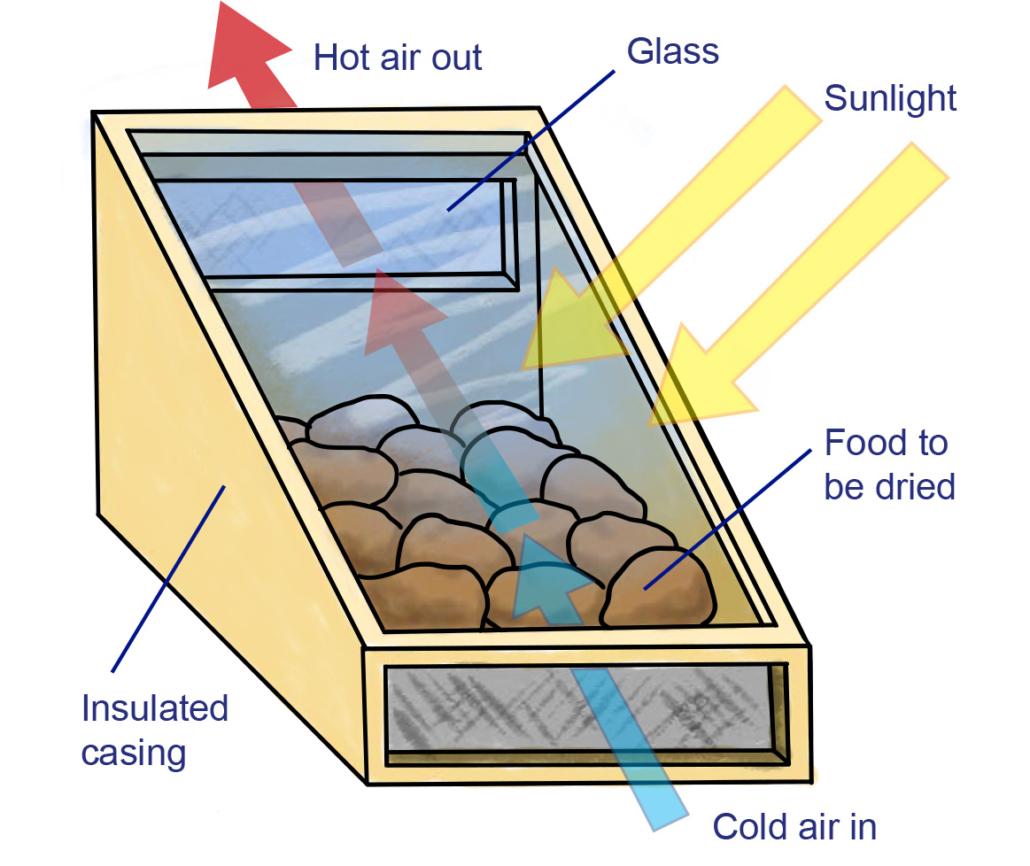

Solar dryers are further categorized as either passive (using natural convection) or active (using powered convection). Within these two main types, there are three different designs for solar dryers: direct, indirect, and mixed-mode. All these systems have a solar collector component often made of glass or plastic, but it can also be a metal surface painted black to optimize solar energy collection. The solar collector absorbs sunlight and converts it into heat energy, which is then transferred to a drying chamber where food crops are spread in a thin layer to maximize exposure to the heated air.

One option for direct solar thermal crop drying is a greenhouse or high-tunnel structure with natural ventilation and screened tables and shelves inside to lay the product to be dried, as shown in the photo below. It is a best practice to add a solar-powered fan to force the circulation of air through the greenhouse or high tunnel.

Direct solar thermal crop drying of coffee beans. Photo: NCAT

A basic indirect solar dryer design, shown in Figure 1, includes an insulated box with a glass window that allows light in, a dark surface that absorbs light and radiates heat, an air inlet that allows cold air in, and an air outlet at a higher point in the dryer box that allows hot air, which naturally rises, out (Muhammad K., 2003). The heat of the sun, which is magnified in the solar dryer, and the natural movement of the air through the dryer work to dehydrate the crops placed in the dryer chamber. To avoid mold, a best practice is to clean the dryer chamber and remove condensation regularly. A solar-powered fan can also be incorporated into the design to lessen condensation and increase dehydration.

Figure 1. Schematic of a Solar Air Dryer. Graphic: NCAT

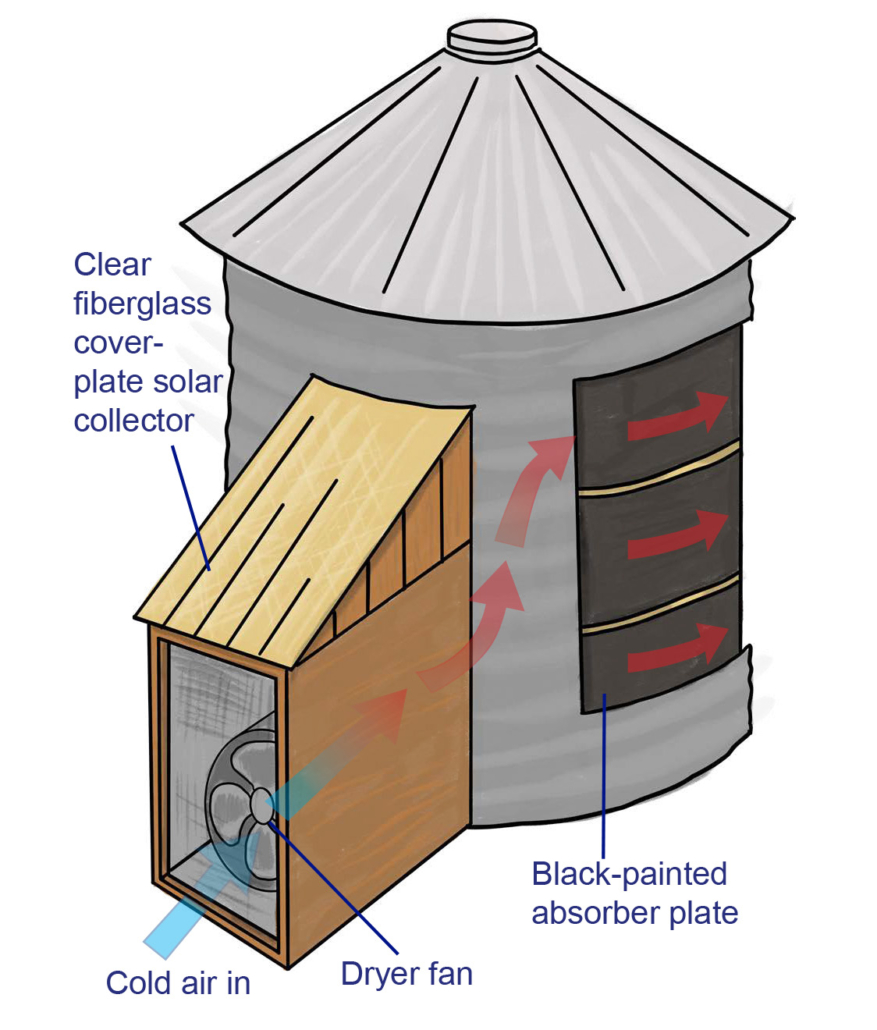

A variation on this design includes the incorporation of a fan, which can be solar-powered, and a drying chamber with crop trays that is separate from the solar collector (Figure 2).

Figure 2. Schematic of Solar Air Dryer with Separate Drying Chamber. Graphic: NCAT

Grain Drying

Grains such as rice, soybeans, corn, and wheat are almost always harvested at a moisture content that is too high for safe storage of the crop. High moisture levels in stored grain lead to spoilage and mold-induced aflatoxins that can ruin the crop and be harmful to animals and humans (NTP, 2021). To prevent this, grain is sometimes dried through natural air drying where air is forced through the perforated bottom of a grain bin and up through the stored grain by a fan. This can work well when the ambient air conditions are dry enough to allow for moisture to be removed from the grain. When the ambient conditions don’t allow for effective natural air drying, a heater is used to help dry the grain. Most stored grain in the U.S. is dried this way.

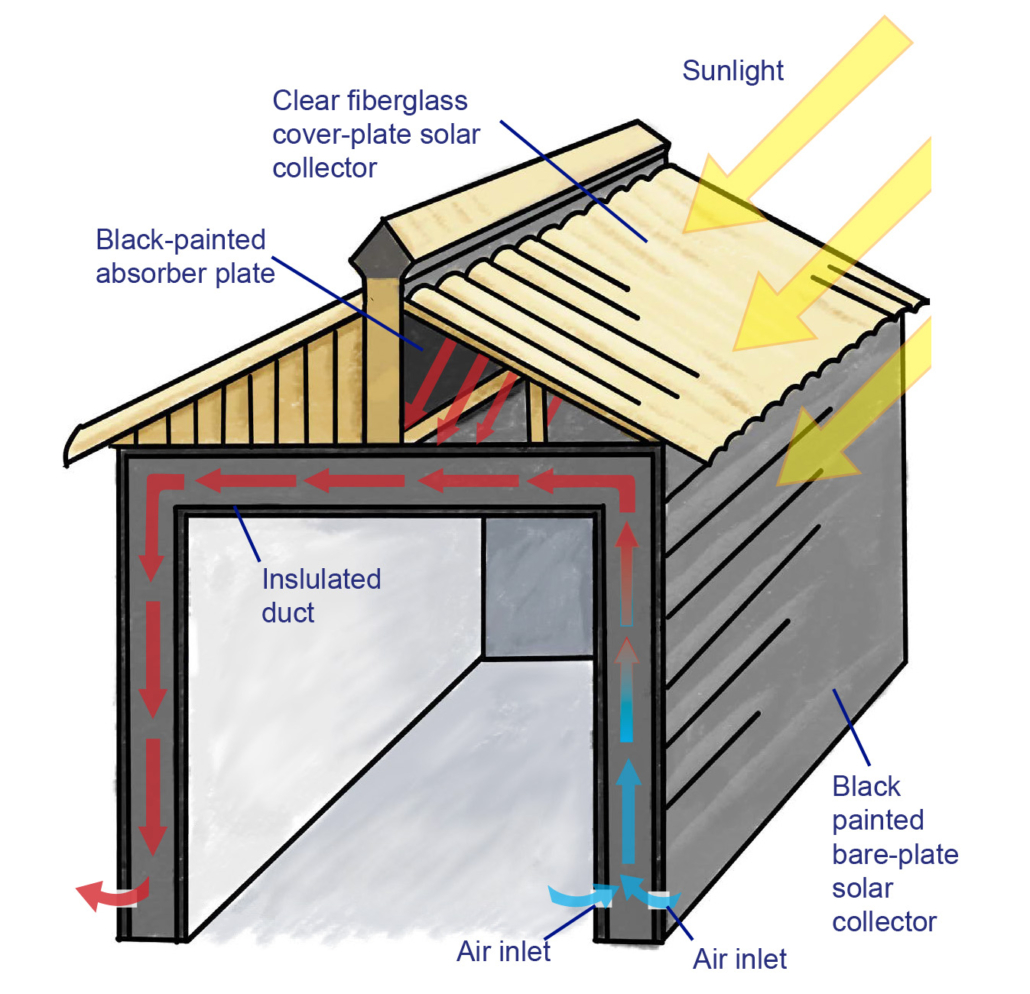

Solar Thermal Buildings and Grain Bins

The metal roof and side walls of an existing or new building can be converted into a solar thermal collector. In this application, the existing metal on the south-facing side of a building is painted black, and wooden purlins are attached to accept a second layer of metal or a clear covering. A metal covering creates what is called a bare-plate solar collector and a clear covering creates a covered-plate solar collector (Figure 3). The solar-heated air is then ducted to an adjacent grain bin. In a similar manner, the bin where the grain is being dried and stored can be converted to a solar thermal collector (Figure 4).

Figure 3. Solar Thermal Building

Figure 4. Solar Thermal Grain Bin

Solar Thermal for Process Water

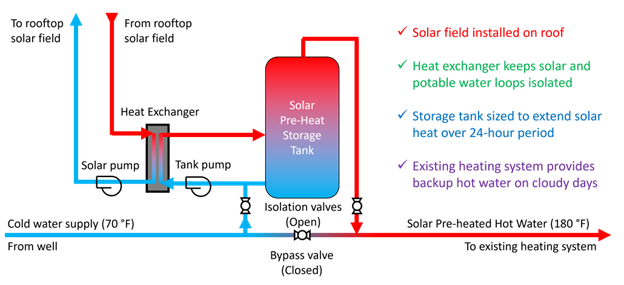

In agricultural operations that require a lot of hot water, like dairy farms, heating water can account for as much as 40% of energy costs. On farms like these, solar thermal water heating can be used to reduce energy costs. Solar water heaters, much like the crop and grain dryers described above, require a solar collector to capture the sun’s energy. Depending on the design, this energy is transferred directly to the water being heated or to a heat transferring fluid, like glycol, that is pumped through a heat exchanger to heat water.

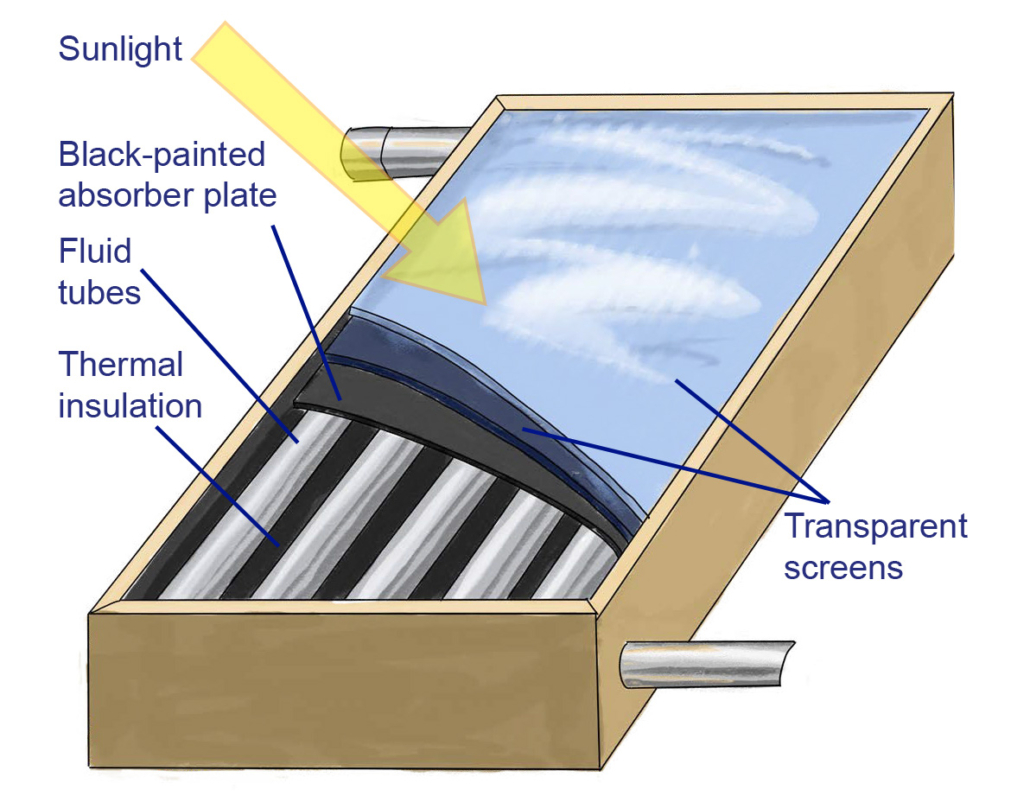

Designs vary for solar water-heating systems, but the basic components are a collector, a heat exchanger, and a hot-water storage tank. A basic schematic of a simple solar hot-water collector in Figure 5 below shows the basic principles of solar hot water heat collection and storage. Like solar dryers, the heat from the sun is transferred through a transparent or semi-transparent medium, like glass, and reservoirs of water behind the medium collect and store the solar heat. This hot water is then used in farm processes.

Figure 5. Simple Solar Thermal Water System (U.S. DOE, 2024)

As shown in Figure 5, solar thermal water systems often include a flat-plate collector. In this type of system, a flat metal plate is attached to metal tubes, which contain a heat transfer fluid that is used to heat water in a storage tank. This type of systems works best for water that does not need to be heated higher than 200°F (U.S. Energy Information Administration, 2024). The main components of a flat-plate solar collector are:

- A black or dark surface that absorbs solar energy.

- A transparent cover that transmits solar radiation to the dark surface but prevents heat loss from the dark surface.

- Tubes containing heat transfer fluid connected to the dark surface. These are often called evacuated tubes because they are designed as a set of two glass tubes, with the air between the tubes removed, or evacuated. This vacuum is created to reduce heat loss.

It is common to build a support structure with insulation around the plate and tubes. Figure 6 is a schematic of a basic flat-plate system.

FIGURE 6. Schematic of a flat-plate solar collector with liquid transport medium. Graphic: NCAT

In the case of Winston Cone Optics, the evacuated tubes are paired with solar reflectors, as shown in the photo below. A schematic of their process is shown in Figure 7. They can heat water, create steam, and deliver process heat up to 350°F with this system.

Winston Cone Optics solar reflectors and evacuated tubes. Photo: Winston Cone Optics

Figure 7. Schematic of Winston Cone Optics. Graphic: Winston Cone Optics

Solar thermal flat-plate collectors heating a high tunnel Photo: NCAT

The photo above shows a solar thermal flat-plate collector array coupled with a high tunnel. In this system, the collectors provide heat for an in-ground hydronic heating system in a 30 X 96-foot-high tunnel. Inside the high tunnel, an insulated 500-gallon, in-ground solar storage tank is heated with the heat transfer fluid circulating through the collector panels. Water circulating through PEX tubing buried under the growing beds is heated from the storage tank via a heat exchanger delivering heat to the root zone of the crops. A back-up heater is used to heat the water for cloudy days when solar can’t be used.

Solar thermal provides an opportunity to harvest sunlight and use the energy tin crop drying, processing, and storage. Solar thermal works by collecting sunlight, converting sunlight to heat, and by transferring heat via airflow or heat transfer fluids. Projects can be as simple as a solar air dryer, or as complex as a concentrated solar heating system for a diary. By working with the sun, thermal energy can help make farm processes more efficient and environmentally friendly while saving significant energy costs.

CONCLUSION

References

Dhumne, L.R. V.H. Bipte, Y.M. Jibhkate. 2015. Solar dryers for Drying Agricultural Products. International Journal of Engineering Research. Vol. 3, S 2. (PDF) Solar Dryers for Drying Agricultural Products (researchgate.net)

Muhammad, Kamran. 2023. Fundamentals of Smart Grid Systems. Academic Press. doi.org/10.1016/C2021-0-02193-3

National Toxicology Program (NTP). 2021. Report on Carcinogens, Fifteenth Edition. U.S. Department of Health and Human Services, Public Health Service. Research Triangle Park, NC.

U.S. Energy Information Administration. 2024. Solar thermal collectors. U.S. Energy Information Administration, Washington, DC.

U.S. Department of Energy. 2024. Solar Water Heaters. energy.gov/energysaver/solar-water-heaters

Access the PDF of this publication here: